시설

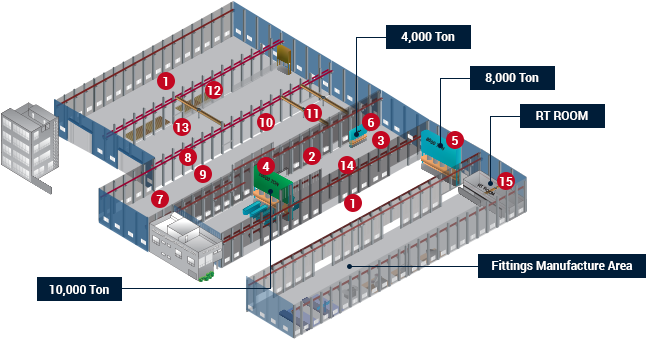

금수커넥팅 시설은 1개의 본사 사무동과 2개의 공장으로 구성됩니다.

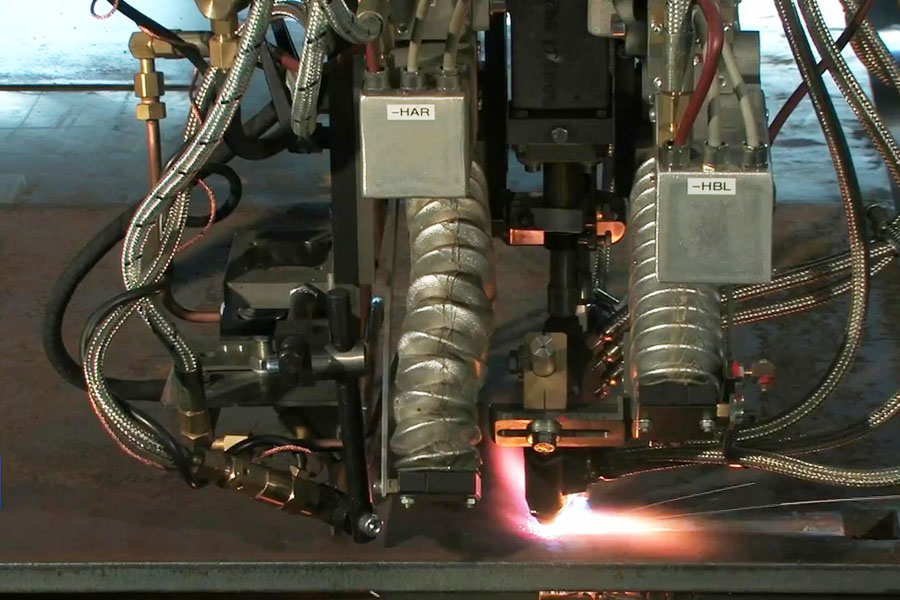

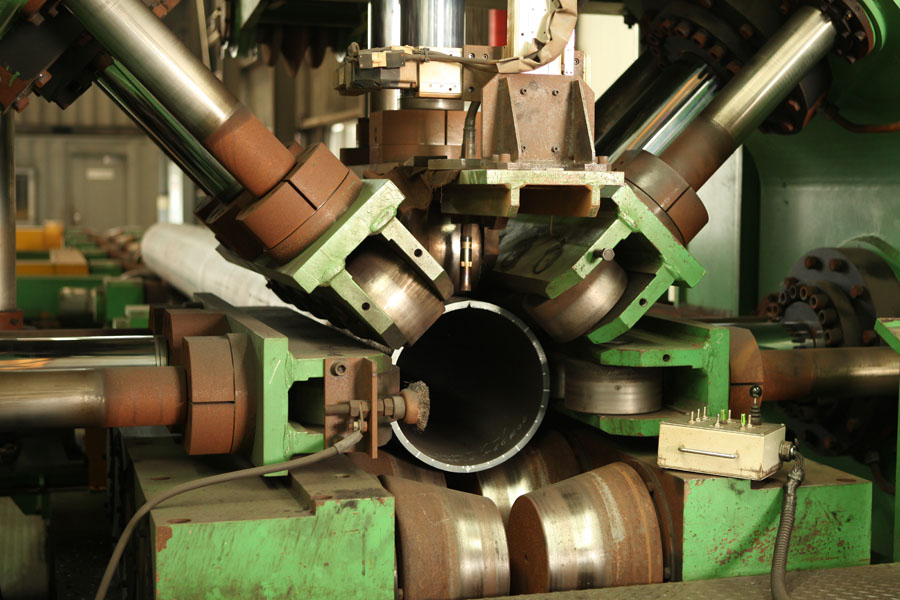

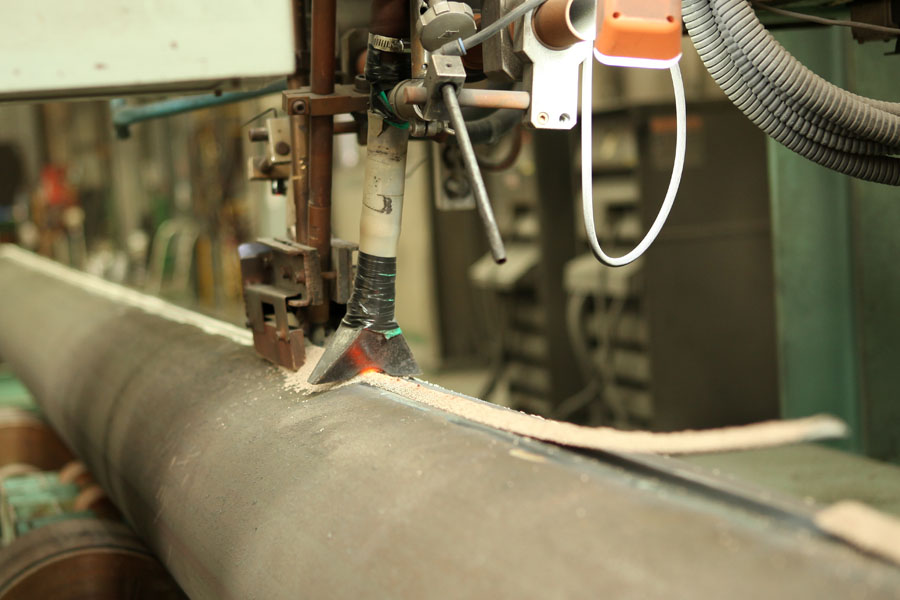

Submerged Arc Welded Pipe 제조를 위한 최신설비를 도입하여 또 한번의 재도약을 진행 중입니다.

공장

- 보유장비

Machinery Working Capacity Q'ty Press Bending machine 10,000 Ton(Cylinder Power) X 12.5M 1 8,000 Ton(Cylinder Power) X 8M 1 4,000 Ton(Cylinder Power) X 4M 1 Roll Bending machine 6,000L X 40Thickness(Max Thickness) 1 4,000L X 110Thickness(Max Thickness) 1 4,500L X 40Thickness(Max Thickness) 1 Tack welding machine Max Thickness : 50mm, Max Length : 15M 1 Long Seam Milling machine Max Thickness : 50mm, Max Length : 15M 1 SAW Inside welding machine Max Length : 15M 1 SAW Inside and outside welding machine Max Length : 12M 1 SAW outside welding machine Max Length : 15M 1 Correction Press machine Workable Weight : 30Ton, Max Length : 15M 1 End Facing machine Workable Weight : 30Ton, Max Length : 15M 1 Hydro Test machine Main Cylinder Power : 350Ton, Pressure : Max 250Bar 1 NDE Inspection Length : 20M, Width : 10M, Height : 5M 1